High Quality for Low Electro Galvanized Iron Wire

By using a full scientific excellent administration method, great quality and fantastic religion, we get good reputation and occupied this discipline for High Quality for Low Electro Galvanized Iron Wire, At present, corporation name has much more than 4000 kinds of products and gained very good status and big shares on current market domestic and abroad.

By using a full scientific excellent administration method, great quality and fantastic religion, we get good reputation and occupied this discipline for Big Coil And Small Coil Electro Galvanized Iron Binding Wire, Direct Galvanized Iron Wire, Low Gi Wire, We have been your reliable partner in international markets with the best quality solutions. Our advantages are innovation, flexibility and reliability which have been built during the last twenty years. We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade items in combination with our excellent pre-sales and after-sales service ensures strong competitiveness in an increasingly globalized market.

DESCRIPTION:

| Product Name: | Steel Wire(black annealed&galvanized) |

| Specification: | 0.175-4.5mm |

| Tolerance: | Thickness:±0.05MM Length:±6mm |

| Technique: | Black annelaed, Electro Galvanized, Hot dipped galvanized. |

| SurfaceTreatment: | Black Annealed,Galvanized |

| Standard: | AISI, ASTM, BS, DIN, GB, JIS |

| Material: | Q195,Q235 |

| Packing: | 1.plastic inside and cartons outside. 2.plastic inside and woven bags outside. 3.water-proof paper inside and woven bags outside. |

| Coil weight: | 500g/coil,700g/coil,8kg/coil,25kg/coil,50kg/coil or can be according to customers’ requirements. |

| Delivery Time: | About 20-40 days after received the deposit. |

| Payment Terms: | T/T, L/C at sight. |

| Loading port: | XINGANG,CHINA |

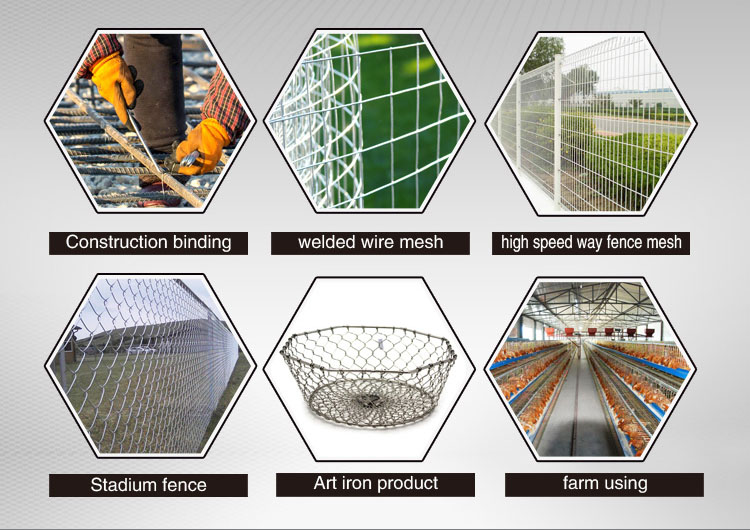

| Application: | Widely used in Construction, Cable, Mesh, Nail, Cage.,etc |

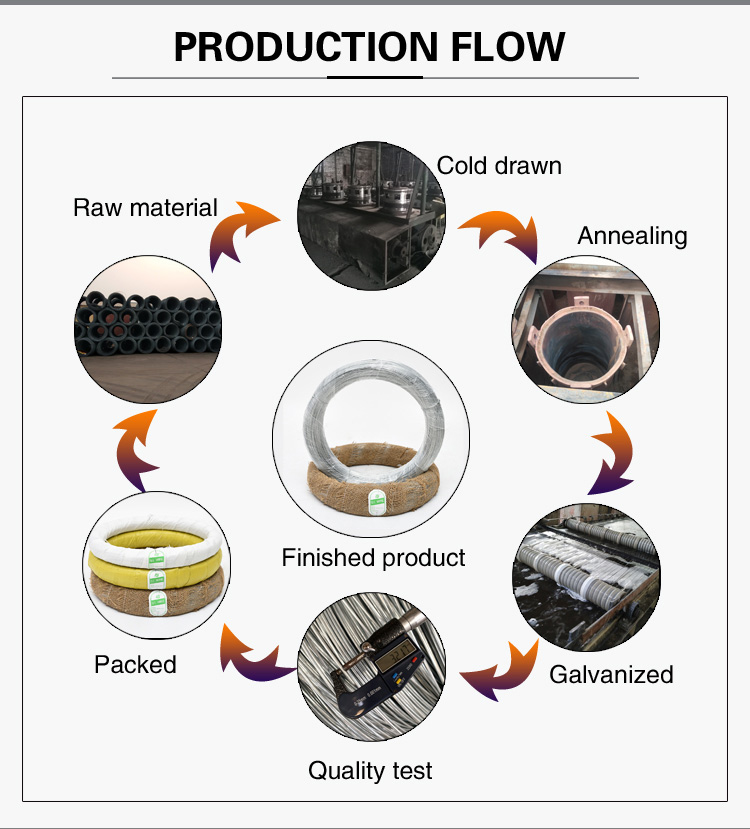

Production process of iron wire

Our galvanized iron wire is made of high quality low carbon steel wire rod. The iron rod is drawn into thinner wire and after drawing molding, pickling derusting, high temperature annealing, cooling processand and galvanization, the wire is produced. Through the plating bath current unipolarity zinc plating on metal surface gradually formed. The production speed is slow, the coating thickness of zinc is uniform, usually only 5 to 20 microns difference. Our product has a bright appearance, high corrosion resistance and generally three to five years anti-rust period.

Please leave your company messages, we will contact you soonest.