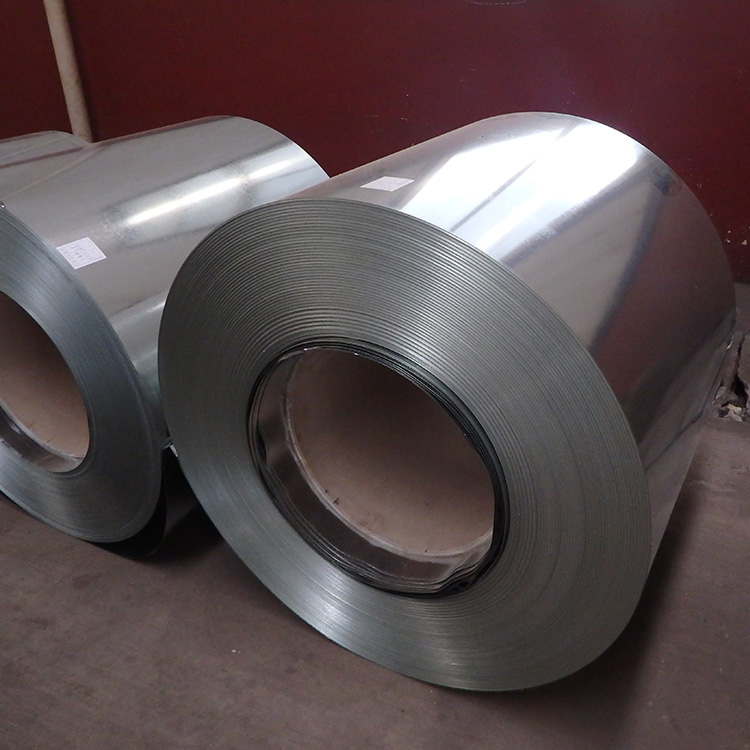

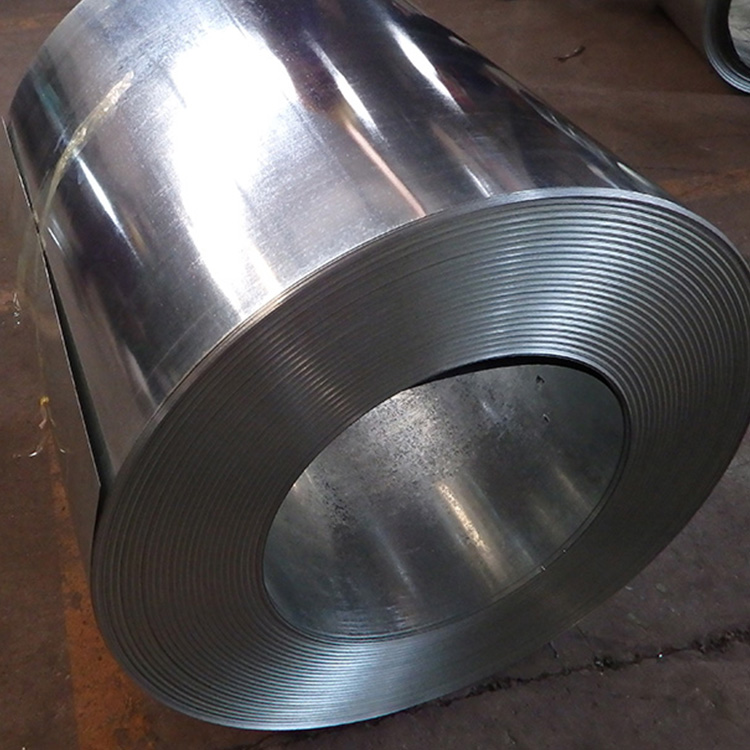

Hot dip galvanized steel coil

| Product Name | Galvanized Steel Coils |

| Thickness | 0.14mm-1.2mm |

| Width | 610mm-1500mm or according to customer’s special request |

| Tolerance | Thickness: ±0.03mm Length:±50mm Width: ±50mm |

| Zinc Coating | 60g-275g |

| Material grade | A653, G3302, EN 10327, EN 10147, BS 2989, DIN 17162 etc. |

| Surface treatment | Chromated unoiled, galvanized |

| Standard | ASTM, JIS, EN, BS, DIN |

| Certificate | ISO, CE |

| Payment terms | 30% T/T deposit in advance, 70% T/T balance within 5 days after B/L copy, 100% Irrevocable L/C at sight, 100% Irrevocable L/C after receive B/L 30-120 days, O/A |

| Delivery times | Within 30 days after the receipt of deposit |

| Package | First with plastic package, then use waterproof paper, finally packed in iron sheet or according to customer’s special request |

| Application range | Widely used for roofs, explosion-proof steel, electrically controlled cabinet sand industrial freezers in the residential and industrial buildings |

| Advantages | 1. Reasonable price with excellent quality

2. Abundant stock and prompt delivery 3. Rich supply and export experience, sincere service

|

♦ Zinc coating

(1) Regular spangle coating

(2) Small spangle coating

(3) Zero spangle coating

♦ Classification and code of surface treatment

Surface treatment symbol

Passivation ---- C

Oiled ---- O

Lacquered seal ----L

Phosphating ---- P

Do not process ---- U

Passivation

Passivation treatment of the galvanized layer can reduce folding rust (white rust) under moisture storage and transportation conditions. However, the anti-corrosion performance of this chemical treatment is limited, and it hinders the adhesion of most coatings. This kind of treatment is generally not used on the zinc-iron alloy coating. In addition to the smooth surface, as a rule, the manufacturer will passivate other types of zinc coatings.

Oiling

Oiling can reduce the corrosion of steel plates under humid storage and transportation conditions. After passivation treatment of steel plates and steel strips, repainting oil will further reduce the corrosion under humid storage conditions. The oil layer should be able to be removed with a degreaser that does not damage the zinc layer.

Paint seal

By coating a very thin transparent organic coating film, it can provide an additional anti-corrosion effect, especially fingerprint resistance. It can improve lubricity during molding and act as an adhesion base layer for subsequent coatings.

Phosphating

Through phosphating treatment, galvanized steel sheets of various coating types can be coated without further treatment except for normal cleaning. This treatment can improve the adhesion and corrosion resistance of the coating, and reduce the risk of corrosion during storage and transportation. After phosphating, it can be used with a suitable lubricant to improve the molding performance.

No processing

Only when the orderer has requested and is responsible for the non-treatment, the steel plates and steel strips supplied in accordance with this standard can be without passivation, oiling, paint sealing or phosphating and other surface treatments.

♦ Application

Galvanized coil products are mainly used in construction, light industry, automobile, agriculture, animal husbandry and fishery and commerce industries. Among them, the construction industry is mainly used to manufacture anti-corrosion industrial and civil building roof panels, roof grilles, etc.; the light industry uses it to manufacture household appliance shells, civil chimneys, kitchen utensils, etc., and the automobile industry is mainly used to manufacture corrosion-resistant parts for cars, etc. ; Agriculture, animal husbandry and fishery are mainly used as food storage and transportation, meat and aquatic products refrigeration processing tools, etc.; commercial mainly used as material storage and transportation, packaging tools, etc.

Please leave your company messages, we will contact you soonest.